MacPherson strut suspension explained: what are they and what do they do?

Most cars use them but are MacPherson struts the best solution for your car’s front suspension?

If you’ve driven a car that was manufactured sometime during the last 80 years then it’s pretty much nailed on that you’ve experienced MacPherson struts in action. Yes, they’re that ubiquitous. Just about every BMW up until the arrival of the F10 generation of 5-series utilised them, and many models still do. Virtually every Porsche 911 has used them. Put simply, the MacPherson strut is one of the most widely used suspension systems in modern automotive design.

However, conventional wisdom has it that for performance cars a double wishbone set up is a better solution so why have so many manufacturers of sporting machinery kept the faith with the MacPherson strut? The simple answer is that for the vast majority of drivers for the vast majority of the time a MacPherson strut type of suspension does its job well and that it’s only in extremis that other systems come into their own.

Named after its inventor, Earl S. MacPherson, who developed the system in the 1940s, this suspension configuration has become a staple in the automotive industry due to its simplicity, cost-effectiveness, and compact design. However, like any engineering solution, the MacPherson strut comes with pros and cons but before we delve into those let’s have a quick look at what makes up a Macpherson strut.

What is a MacPherson strut?

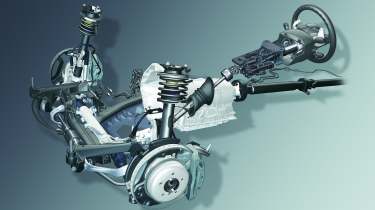

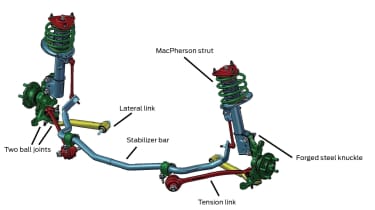

It effectively combines the functions of a damper and a spring into a single compact unit, simplifying the design and reducing the overall weight of the suspension system. Its main component is the strut assembly which includes a damper and a coil spring with the damper controlling the motion of the spring to reduce oscillations and hopefully provide a smooth ride.

The strut assembly is attached to the car’s chassis via a strut mount. This mount allows the strut to pivot as the wheels turn, contributing to the vehicle's steering. The bottom of the strut assembly is connected to the lower control arm, which is attached to the vehicle's chassis or subframe. The lower control arm helps to control the vertical movement of the wheel.

> Coilover suspension explained: different types of coilovers and what they do

The wheel carrier (or upright or steering knuckle) connects the strut assembly to the wheel hub and allows the wheel to pivot for steering. It also houses the wheel bearings and provides attachment points for the brake components.

How does a MacPherson strut work

The main job of the coil spring is to support the vehicle’s weight and maintain its ride height. When the vehicle encounters a bump or pothole, the wheel moves upward, compressing the coil spring further.

The damper within the strut assembly dampens this motion, preventing the spring from oscillating uncontrollably and ensuring the wheel returns to its normal position smoothly. The MacPherson strut helps to maintain proper wheel alignment by controlling the vertical movement of the wheel. The lower control arm and the strut assembly work together to keep the wheel in the correct position relative to the vehicle's chassis.

> Differentials explained: how does a car’s diff work?

The strut mount at the top of the strut assembly allows the entire strut to pivot when the steering wheel is turned. This pivoting motion is transferred to the wheel carrier, which turns the wheel in the desired direction.

Advantages of the MacPherson Strut

One of the most significant advantages of the MacPherson strut is its compact design which allows manufacturers to maximise interior cabin space and boot capacity. By combining the shock absorber and coil spring into a single unit, the system takes up less space compared to more complex suspension setups like double-wishbone or multi-link systems.

The bean counters are never far away from the design process and they favour the MacPherson strut as it’s relatively inexpensive to manufacture and install. Its simple design requires fewer components, reducing production costs and assembly time. This also pays dividends to owners as the reduced number of parts equates to lower running costs as there are fewer components to wear out or fail over time.

The MacPherson strut’s simplicity also contributes to its lightweight nature and by eliminating the need for additional control arms and linkages, the system reduces the overall weight of the suspension assembly.

MacPherson Strut limitations

Despite its use in many high-performance cars the MacPherson strut is theoretically not well-suited for these vehicles. The system’s design inherently limits its ability to handle extreme cornering forces and the single lower control arm and vertical strut configuration can lead to increased camber changes during hard cornering.

While the MacPherson strut provides adequate ride comfort for most drivers, it may fall short in more demanding conditions. The system’s simplicity can result in a less refined ride quality, particularly on rough or uneven roads. The vertical orientation of the strut can transmit more road noise and vibrations into the vehicle’s cabin, too.

The MacPherson strut’s design also offers limited opportunities for adjusting a car’s setup. Unlike more advanced suspension systems like the double wishbone it is difficult to adjust camber, caster or toe angles without significant modifications. This lack of adjustability can be a drawback for drivers who want to tailor their vehicle’s handling to suit their driving style.

There’s also the possibility that the MacPherson strut’s single-point attachment to the vehicle’s chassis can make it less durable under heavy loads. Over time the strut mount and even the sheet metal of the suspension turret may experience increased wear and tear. In theory, a MacPherson strut’s design can also impact steering feel and feedback.

The system’s vertical orientation and single lower control arm can result in less precise steering response when compared to more sophisticated suspension setups.

It’s not something most Porsche 911 owners complain about so perhaps some manufacturers are better at combatting these limitations than others.